Canal linings

Canals are extensive linear surface features which are normally trapezoidal in cross section and transport and convey liquids of diverse types and compositions from source to storage, often over vast distances. Canal linings can be used in isolation or in combination with shotcrete or concrete overlays. These linings need to be robust to prevent damage during construction and need to remain stable and intact over the operational life of the structure. Rowad linings are an essential element in achieving these objectives and preventing seepage loss while protecting the environment in sensitive geological areas.

Lined security bunds for the petrochemical industry

Tank storage facilities for the petrochemical industry can hold large volumes of product and are designed with surrounding security bunds to contain any catastrophic spillage which might occur. While most liner systems are not acceptable for use as primary liners in direct contact with hydrocarbon-rich liquids, they represent the best solution for emergency capture of spillage and for the protection of the environment as secondary liners as they prevent direct contact of product with the local environment and allow sufficient time for the removal of spilled product from the area in the aftermath of a failure.

Aquaculture and fish farming

Flexible geomembrane linings, which are non-toxic, chemically inert and durable, are imperative for the stocking and breeding on a commercial scale of aquaculture and mari culture species. Smooth membranes are the preferred choice due to the fact that they do not allow the attachment of micro- organisms, they do not damage fins and tails, they are easily cleaned and maintained and improve overall pump efficiencies.

Waste water treatment lagoons

In sewage and waste water treatment facilities, it is imperative that any selected liner system is proven to be resistant not only to the effects of climate but also resistant to the potential attack of chemicals, highly organic fatty acids and oils in the long term. The design and installation of liner systems for these application areas warrant a very detailed approach to the mechanical and physical forces to which they would be subjected during both operation and maintenance cycles.

Land fill basal linings and cap closures

The geomembrane liner in basal applications should be the most effective line of defense in protecting the environment and is generally the lowest cost component of the total cost of a project.

These linings often form one essential component of a lining system in what is a natural bioreactor and prevents potentially harmful leachate which is produced by decomposing organic compounds. Such linings should be extremely durable and resistant to the components of these organic liquids over many decades, often centuries.

At the end of life of land fills, the site is capped with a suitable liner and used in the closure and rehabilitation of these sites. A development which is receiving increasing use is the incorporation of a gas collection and removal system below and through the cap to draw gas into turbines for the generation of electricity.

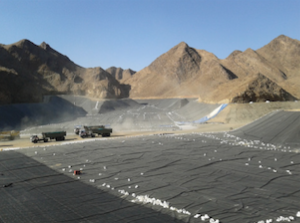

Oil and gas disposal pits

Exploration for oil and gas requires extensive drilling which creates a good deal of slurry and waste that can be harmful to the environment. Storage pits are constructed and used during this process and are lined with HDPE linings to store the slurry and protect the local soil from contaminants. It is important that robust and durable linings are used for this purpose and Rowad linings play a vital role in this process.

Surface reservoirs ponds and lagoons

Flexible geomembrane lining systems constitute what is quickly becoming the first choice for clients wishing to provide a fast, cost–effective means of storing their liquids in earth dams, lagoons and ponds.

Evaporation and retention ponds

The liner systems used in these facilities are often more critical in terms of aspects of design selection and installation. This is mainly due to a much greater hydraulic head of chemically–charged solutions exerted upon the liner system. To cope with this additional need for security against potential leakage, the liner system is often designed with thicker membranes and can comprise multiple layers with intermediate drainage layers for the purpose of detecting and collecting any leakage.

A growing and important application is the use of linings over permeable soils in the production of commercial salt projects where the linings allow retention of brine within a series of shallow evaporation ponds leading via decanting structures to the final harvesting areas. Here, salt of a specific purity can be produced and extracted before being processed in the nearby plant for washing, crushing, grading packing and dispatch to market.

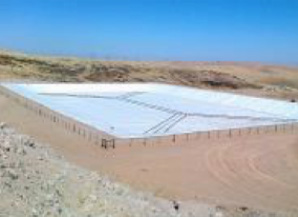

Potable water reservoirs

The storage and supply of drinking water is becoming a crucial part of supporting the development and growth of populations in existing and new geographic areas. Traditionally, concrete has been used to store water, but with the advent of geomembrane linings, a quicker and more cost effective means for construction and operation has been achieved. The geomembranes not only store water in the conventional way but overcome the need for extensive and ongoing maintenance of concrete joints and cracks over time. The roof is constructed in the form of a floating geomembrane cover which can be adapted to any size and shape of reservoir and sits on the water surface floating up and down as the water level fluctuates. This assists in maintaining water quality at the desired levels by preventing dust and debris from entering the stored water body and overcomes issues of evaporation loss in hot equatorial zones.